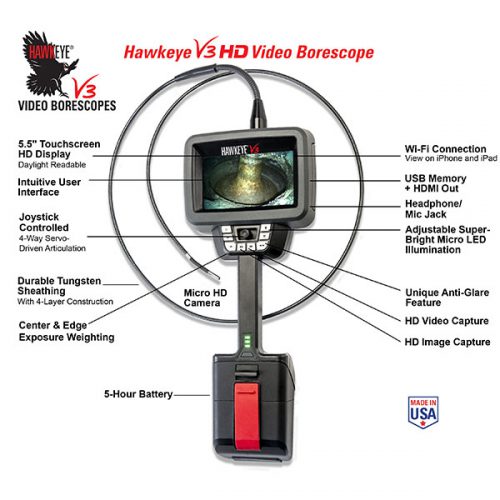

Hawkeye Q2 Micro Video Borescope

HD Micro Videoscope with a slim 0.95mm diameter

Thanks to the Q2 Micro Videoscope, inspection and quality control teams can now successfully inspect small parts using HD video technology. Whether you need to check surface detail or burrs on thin tubes, pipes, engine components or any other precision manufactured part, the Hawkeye Q2 Micro Video Borescope is a reliable option.

This HD videoscope boasts full screen, high resolution imagery which is a huge 8x the resolution of the 1mm Pro MicroFlex Fibrescope, while benefiting from a more compact and portable design. Take advantage of 1m and 2m lengths for inspecting hard-to-access areas, including those with tight bends, making it perfect for most precision inspection applications within automotive and aerospace industries. The 4-hour battery life and portable design allows users to take the Hawkeye HD Micro Video Borescope anywhere for a more flexible approach to remote visual inspection.

Purchase the slim HD Micro Videoscope on its own or as part of a kit including a micro-SD card, micro-SD to USB convertor, cables and a handy carry case. Additional insertion tubes are also available to purchase directly through Optimax Inspection and Imaging.

Specifications

- 1 Mp Micro High Definition camera

- Adjustable super-bright micro LED illumination

- Durable stainless steel spring sheath

- 5" HD display

- Available as a kit which includes a micro-SD card, a micro-SD to USB convertor, cables and a carry case.

- Diameter: 0.95mm

- Lengths: 1m and 2m

- Field of View: 100° diagonal

- Direction of View: 0°

- Depth of Field: 1.5mm - ∞

- Battery run time: 4 hours

- Operating Temperature Range: Probe -20 to +60C, Display -10 to +50C

- Weight: 1KG

- Additional insertion tubes

- Spare battery

- Replacement cables

- Replacement case

Case Study

Baseload Power maintain and repair high power generator plants, often gas turbine, for utility companies Read how their use of video endoscopes both saves time and money during maintenance but also, through the images and video captured, allows wear and fault progress to be assessed.