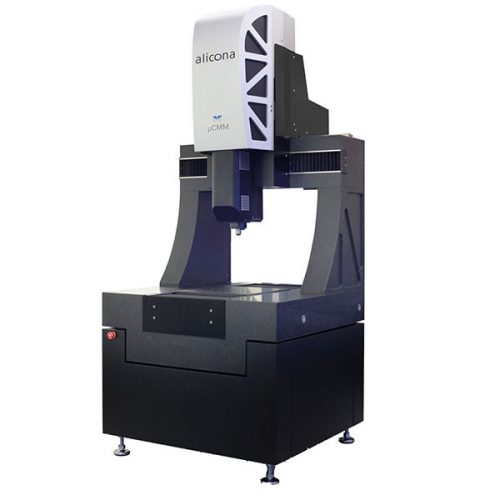

Alicona InfiniteFocus G6

Optical 3D measurement device for μm and sub-μm tolerances

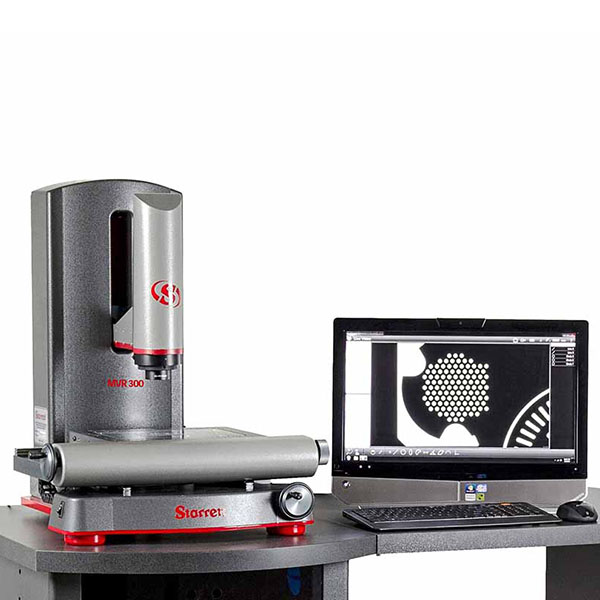

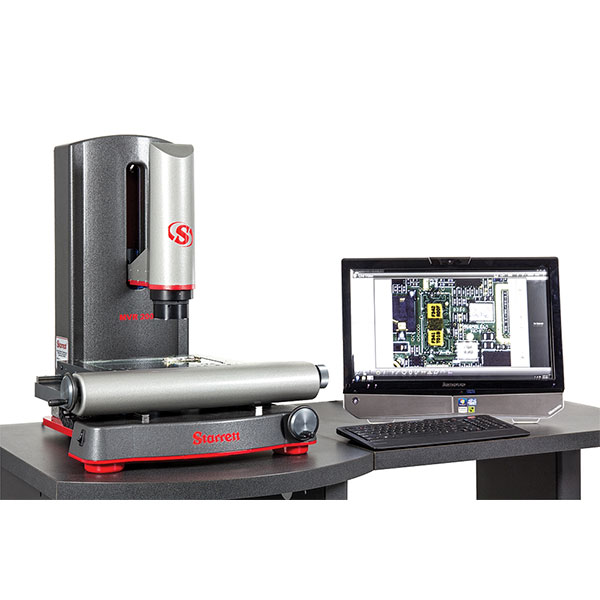

If you’re looking for an accurate, fast and universal non-contact 3D optical metrology instrument, look no further than the Alicona InfiniteFocus G6. Slightly larger than the more compact Alicona FocusX, the G6 uses Advanced Focus-variation to combine the functionality of a surface roughness measurement device (Ra, Rq, Rz/Sa, Sq, Sz) with the sought-after features of a coordinate measuring machine (CMM). Using just one optical sensor, the 6th generation InfiniteFocus can measure both form and roughness in high resolution within the μm and sub-μm range.

The InfiniteFocus G6 takes areal-based measurements of simple and complex components and offers high resolution inspection regardless of size, material, geometry, weight and surface finish. And thanks to SmartFlash technology, the G6 will measure smooth, reflective and highly polished surfaces in high-resolution.

With vibration-recognition built in, the InfiniteFocus G6 can deliver exceptional results, even when placed next to the machine tool, making the entire process more streamlined than ever. Combine the Infinite Focus G6 with your existing CAD systems for offline optical measurement planning or situate the non-contact measurement device within your manufacturing setting for real time results.

Specifications

- Fast axes and innovative optics with modern algorithms ensure short measurement times

- The MetMaX software sets new standards in usability

- Single-button solutions and automated measurement sequences ensure efficient workflows and measurements without user interaction

- High lateral and vertical resolution

- High repeatability and areal based measurements with high point density

- Traceable and compliant with international standards

- Non-contact, optical, three-dimensional

- Technologies: Advanced Focus-Variation (SmartFlash 2.0), Vertical Focus Probing, Real3D

- Positioning volume (R x T): AdvancedReal3DUnit (optional): Motorized rotation: 360° / Motorized tilt: - 15° to + 90°

Case Study

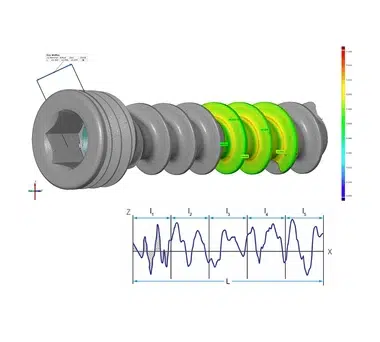

Bone screw measurement with roughness profile

The Real3D technology empowers users to capture comprehensive form/shape measurements of components in a full 360° view. Here, a direct comparison to the respective CAD data set is shown. Plus, measure surface roughness for comprehensive insights.