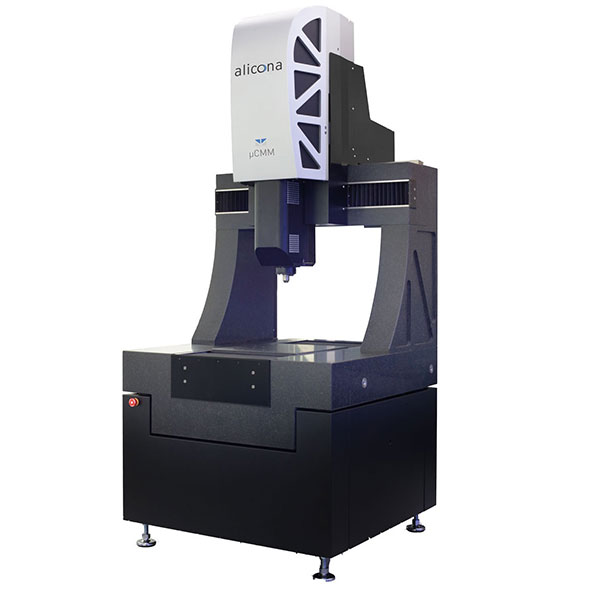

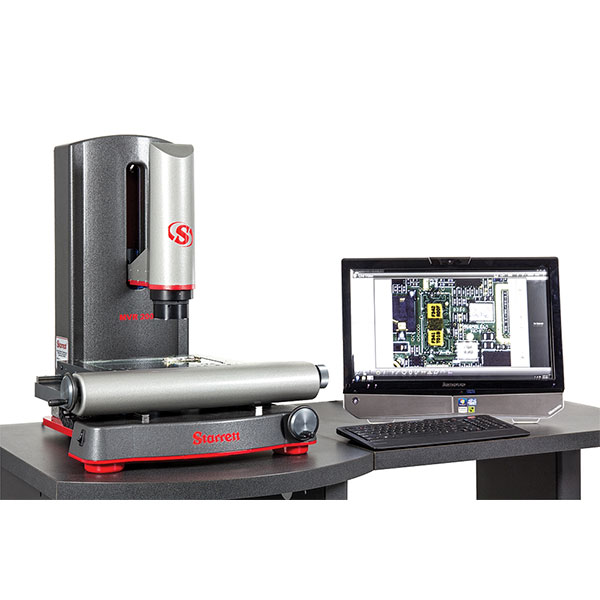

Alicona µCMM

Non-contact optical metrology system: Coordinate measuring machine (µCMM)

The Alicona µCMM is an optical three-dimensional coordinate measuring machine (CMM) combining the advantages of tactile CMM technology and Optical Surface Metrology providing traceable GD&T, and measurement of dimension, position, shape, and surface finish.

It is exactly accurate over the entire measurement volume providing high accuracy positional location of multiple optical 3D measurements to each other.

Using Advanced Focus Variation, it combines the functionality of a surface roughness and surface texture measurement device (Ra, Rq, Rz/Sa, Sq, Sz) with full features of a CMM working in the μm and sub-μm range by applying nanometer (nm) resolution

“How do I measure?” to “What do I measure?” is the core thinking behind MetMaX, the µCMM operating software. This allows users without any specific metrology knowledge to perform robust measurements with the µCMM with set up from CAD and working with Digital Twins to create automated regimes

Adding a rotation device creates a 5-Axis machine, allowing the full geometry measurement of cylindrical products such as cutting tools and fuel injection nozzles.

Application areas commonly in use include Cutting Tools, Aerospace, Automotive, Medical, Electroforming, both on the shop floor and in the measurement room

Designed specifically for the production environment, the Alicona µCMM is the most accurate, purely optical micro-coordinate measuring system in its class. The µCMM combines the advantages of tactile coordinate measuring technology with optical surface measuring technology with Focus-Variation for the ultimate non-contact metrology experience.

Specifications

- Measurement of dimension, position, shape and roughness in one system

- High accuracy over the entire measurement volume

- Non-contact, optical measurement with Focus Variation

- Fast measurement of components

- Solid granite construction with active temperature compensation

- Expandable – 3-axis system turns into 5-axis system

- Most accurate purely optical micro-coordinate measuring system in its class

- Non-contact, optical, three-dimensional, based on Focus-Variation incl. Vertical Focus Probing technology

- Single measurement: X: 1720, Y: 1720, X x Y: 2.95 Mio. multi measurement: up to 500 Mio

- Positioning volume (X x Y x Z): 310 mm x 310 mm x 310 mm = 29 791 000 mm

- EUni:Tr:ODS,MPE = (0.8 + L/600) μm (L in mm) Axis accuracy based on ISO 10360-8. EUniZ:St:ODS,MPE = (0.15 + L/50) μm (L in mm)

Case Study

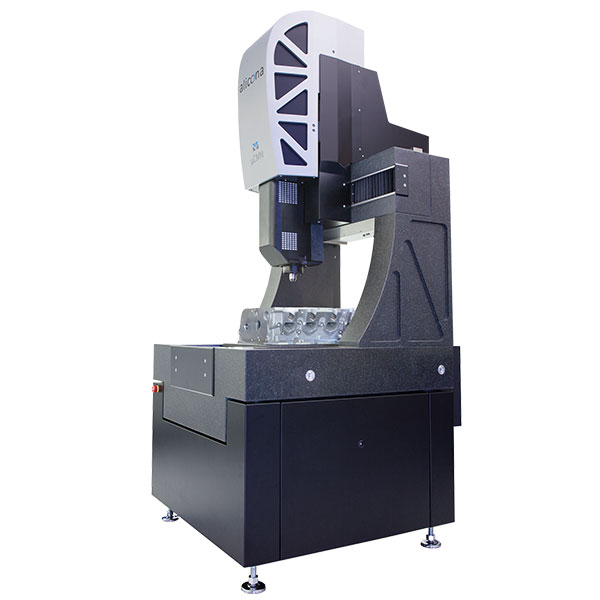

Gear shaft malfunction inspection with the optical CMM machine

The µCMM optical CMM machine with a µCMM Real3D rotation unit was used to measure a faulty gear shaft. In order to analyze the malfunction of this gear shaft part, the following parameters need to be measured:

- coaxiality of gearing in respect to the shaft

- outer diameter of gearing and shaft areas

- shaft lengths

- profile & areal roughness on the tooth flank

- parameters to qualify the gearing itself

An automated routine was developed. The component is clamped in the Real3D rotation unit and for shape, distance and position measurements the 1500A objective is used. Then for surface finish measurements the system automatically switches to a 800A objective. The routine measures and assesses sample areas of the component, taking in total less than 10 minutes.