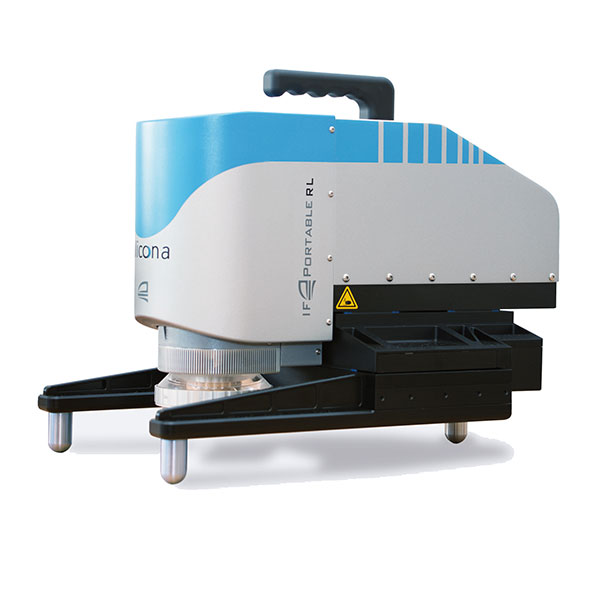

Alicona Cobot

Verify surface quality & dimensional accuracy of small features on large components

The Alicona cobot range is based on the combination of a collaborative 6-axis robot and the robust optical 3D measurement sensor IF-SensorR25, delivering high resolution, traceable and repeatable measurements.

Collaborative systems are tailored to the individual measurement task and application. Programming and measuring as well as handling of pre-defined measurement programs require no prior knowledge of metrology.

Specifications

- Intelligent interaction between man and robot

- Easy coarse positioning with two handle bars

- Fine positioning with integrated joysticks at measurement sensor

- Live-View via smartphone app for highly accurate measurement

- Safety: collaborative - stops at collision with an object

- Connection to automation software

- UR-10 robot type

- Specimen radius is 1300 mm

- Axes: 6 rotating joints

- Repeatablitiy: +/- 0.1 mm

- IF-SensorR25 - travel range in Z 26 mm motorized - LED travel ring light with 24 segments - 126 mm x 153 mm x 202 mm (W x D x H)

Case Study

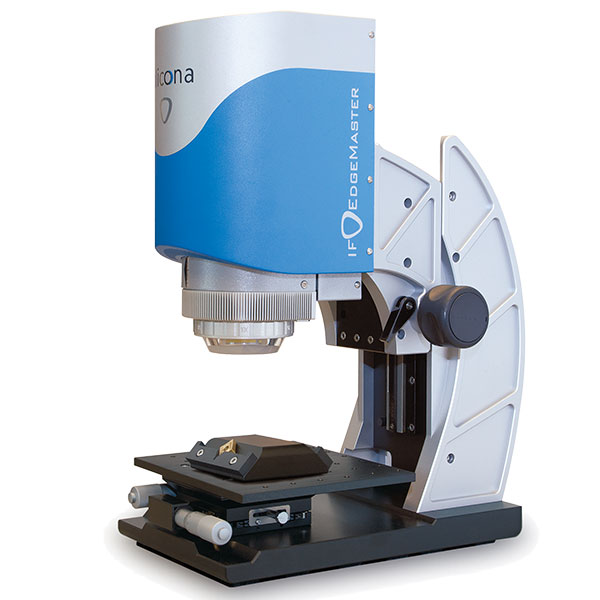

DiscCobot: Evaluation of break edges

The DiscCobot is used for the quality assurance of large rotationally symmetric components up to 120 kg. In particular, the Cobot is applied in the standardized evaluation of edge breaks.

By verifying minimal radii, it prevents sharp edges that can, in the worst case, compromise aircraft safety. The DiscCobot is used in the aircraft industry for the measurement of e.g. turbine housings and turbine discs as well as in the tool industry e.g. for the cutting edge measurement of saw blades