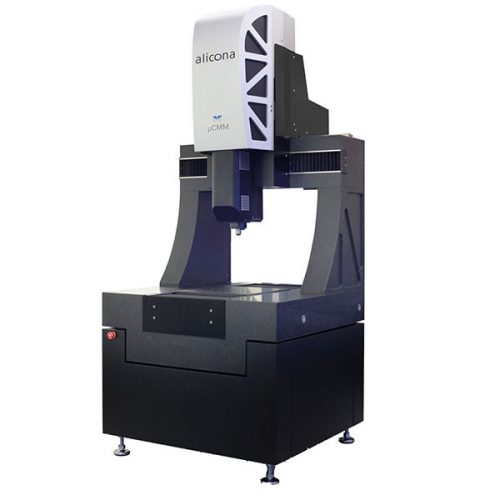

Alicona EdgeMaster X

Fully automated, non-contact cutting tool measuring device

Are you ready to experience the very best in automated optical metrology for your cutting tools? The EdgeMasterX allows integrated quality assurance throughout the production process to ensure inserts, drills, mills and other round tools are performing with maximum accuracy.

Unlike other non-contact cutting tool measurement devices, the EdgeMasterX enables automated multi-edge measurement of cutting tools in a single run. Achieve a complete series of user-defined measurements at multiple edge positions with minimal disruption to your manufacturing process.

The measuring and inspection of cutting tools is essential across all markets, but especially in medical, automotive, aerospace and other precision engineering departments. With even the smallest discrepancies causing havoc on production lines, fast, flexible and accurate non-contact metrology is the backbone of the operation. The EdgeMasterX has it all.

Specifications

- Verify multiple edges in one measurement run

- Optical, high-resolution tool measurement in production

- An extension of the EdgeMaster

- Measurement of different edge parameters on different positions of a tool

- Measurement of user-defined parameters on tools of a batch

- In combination with a rotation unit, chamfered cutting edges detected in one measuring run

- Non-contact, optical, three-dimensional, based at Focus-Variation

- Positioning volume (X x Y x Z): RL objectives: mot.: 50 mm x 50 mm x 155 mm (Z: 25 mm mot., 130 mm man.) = 387500 mm³

- SXRL/AXRL objectives: mot.: 50 mm x 50 mm x 120 mm (Z: 25 mm mot., 95 mm man.) = 300000 mm³