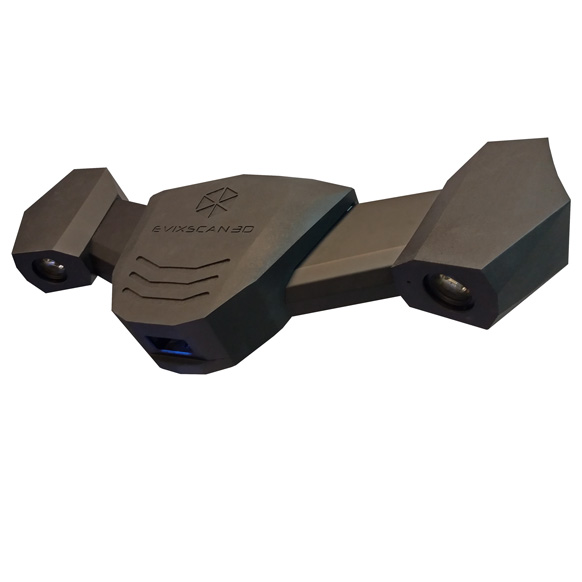

EviXscan FinePrecision for Quality Control

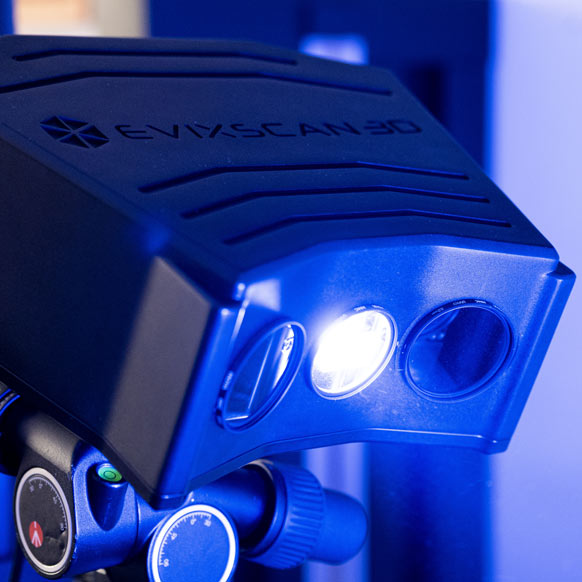

High quality 3D scanner based on structured light technology

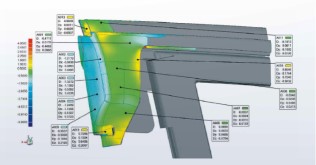

Collect true 3D surface data rapidly and with superb accuracy. Full GD&T capability with the Geomagic Control X software suite to ensure quality everywhere.

The FinePrecision scanner is designed for measuring very small parts from 2mm to 120mm. The results are superb accuracy scans with the highest point density in the EviXscan range and a short data acquistion time of under 1 second.

Particularly suited to fine mechanics, aerospace, electronics, turbine blades, autosport and research.

Specifications

- True 3D surface model data collection of small parts

- Whole surface and all geometric element measurements in a single operation

- Surface preparation not normally required

- Easy transfer of data between different software packages

- Extract traditional GD&T parameters or reverse engineer fully automatically

- Designed for the production environment

- High accuracy and fast scanning time

- Easy to change scanning range with no need for re-calibration

- High point density for maximum geometry capture

- High quality pattern display with 1080 Mpix Blue LED projector

- Cobot and robot integration

- EviXscan 3D Suite 2.8 software as standard for optimum speed and quality

- Minimum scanned object size 2-3mm

- Maximum scanned object size 100-120mm

- Measuring range 120 x 60 x 32mm

- Camera resolution 9 Mpix

- Point density 1233 pts/mm2

Case Study

Cooper Standard Automotive is a leading supplier of plastic and rubber components for the automotive industry.

Learn how they have successfully integrated EviXscan 3D scanners into their production processes for Quality Control, Reverse Engineering and Rapid Prototyping, shortening production time and lowering costs.