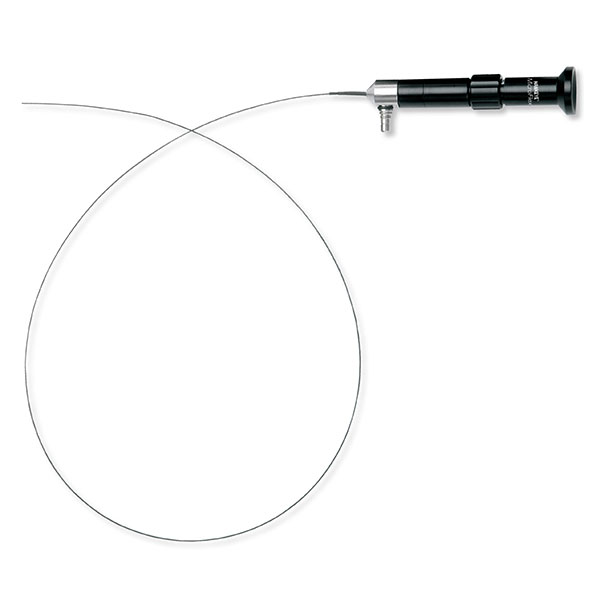

Hawkeye Pro MicroFlex Flexible Borescope

Flexible borescope with incredible resolution

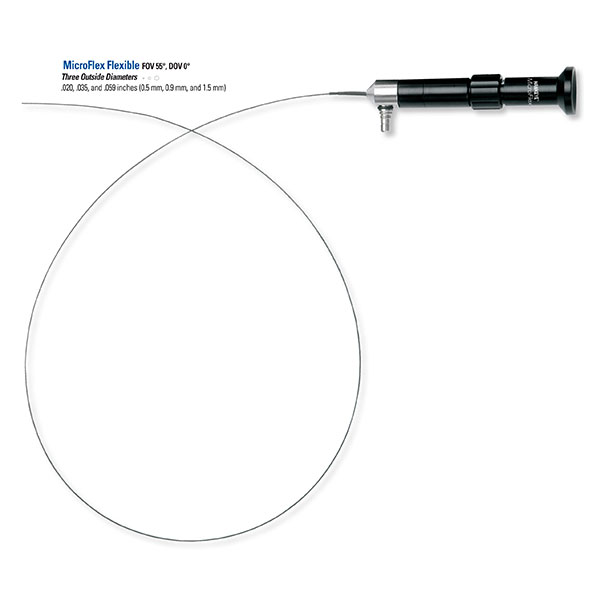

The Hawkeye Pro MicroFlex is the slimmest borescope with diameters of just 0.5mm – 1.5mm. Despite its micro size, the Pro MicroFlex offers incredibly high quality image capture within some of the smallest access areas.

Available in different variations, the Pro MicroFlex is a truly versatile flexible microscope. Currently available from Optimax in the following options: 0.5mm (600mm length), 0.9mm (1000mm length) and 1.5mm (800mm length). Not only does the MicroFlex deliver outstanding image quality, the eyepiece can be replaced with a video adapter to attach a C-mount camera for high quality video inspection too.

The flexible Hawkeye Pro MicroFlex borescope is used to quickly and easily inspect cooling holes inside turbine blades, cannulas, catheters, cross drill holes, needles, trocars, valves in medical devices and many other micro-manufactured parts. When precision is key, this ultra-slim industrial borescope is up for the job.

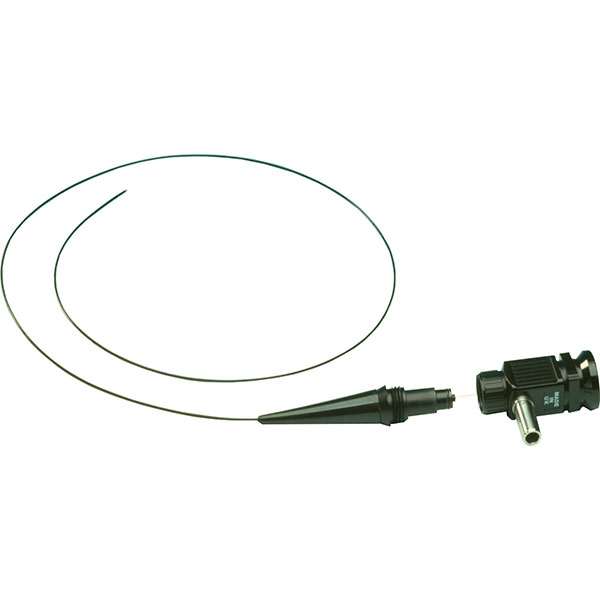

The Hawkeye MicroFlex Flexible Borescope is available as part of a kit with a C-mount adapter, rugged Hawkeye carrying case and Hawkeye cleaning kit.

Specifications

- Excellent image quality

- Polyamide-sheathed 0.5mm models have a 3000 fibre bundle and 0.9mm models have 10,000 fibre bundle

- Plastic sheathed 1.5 mm model has a 30,000 fibre bundle

- Eyepiece easily replaceable with a C-Mount video adaptor

- Fixed focus lens set

- No articulation

- Diameter: 0.5mm, 0.9mm and 1.5mm

- Length: 0.6m, 0.8m, 1.0m

- DOV for all models: 0°

- FOV: 55° (0.5mm and 0.9mm), 70° (1.5mm)

- Depth of Field: 1-3mm (0.5mm), 2-5mm (0.9mm), 3-10mm (1.5mm)

- Luxxor 35 LED Light Source

- Haweye SuperNOVA LED Light Source

- Luxxor Light Guide

- Luxxor 50 Light Source

- Hawkeye LED Light

Case Study

Kreisler Industries manufacture tube and manifold assemblies for aircraft engines. Their goal is zero customer returns and to help achieve that, their welders are trained to inspect their own work using Hawkeye borescopes. This empowers them to adjust the weld parameters without waiting for the results of end of line inspection.