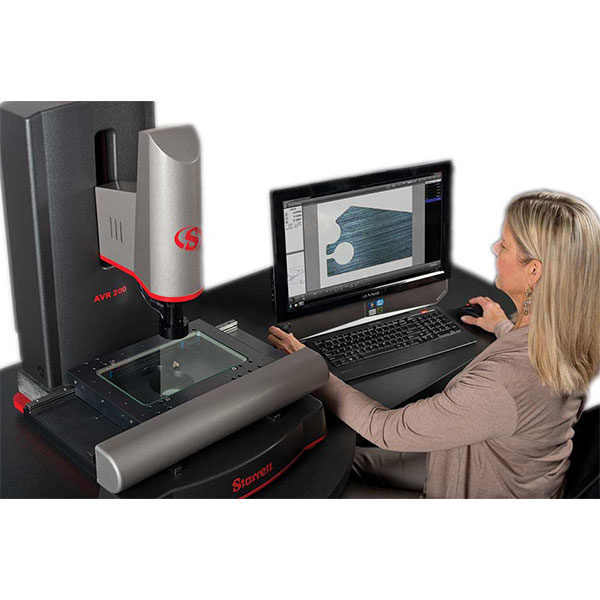

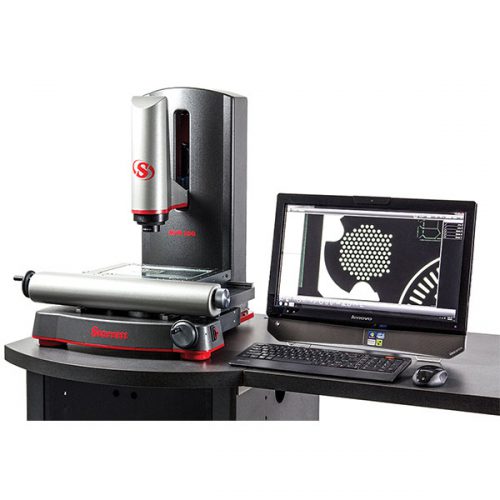

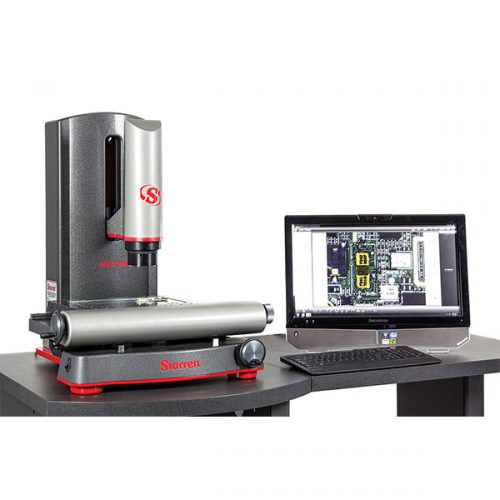

Starrett AVR200 FOV

CNC Vision machine ideal for repetitive measurement and comparison to CAD files

The AVR200 CNC Automatic Vision Metrology System is ideal for repetitive measurements and automatic comparison to CAD files. Systems are available with interchangeable telecentric or dedicated zoom lenses for micron-level resolution and accurate field-of-view (FOV) measurements. With a maximum FOV of 0.93″ (24mm), the AVR200 is capable of measuring parts with a length up to 200mm. A large 2.36″ (60mm) FOV-dedicated 0.14X lens is now available.

The operator interface is the MetLogix™ M3 software that displays a live video image of the part plus geometry tools and digital readings. The image of the part can be resized using zoom and measurements can be taken by simply touching a feature on the touch-screen monitor. M3 software capabilities also include 3-axis measurements and 2D geometric constructs (points, lines, angles, rectangles, slots, blobs). Systems are also touch probe compatible.

Specifications

- Bench top system with Granite base

- Full CNC operation

- Z axis measuring as standard

- Metlogix M3 Software with video edge detection

- Field of View measurements integrated with stage motion 24" Touchscreen PC Display

- Digital Video Camera: 1.3 MP colour (2.0 MP with telecentric)

- LED surface ring and transmitted illumination (optional coaxial)

If you have any questions, or would like to hear more about this instrument feel free to get in touch

- Type of system: Bench-Top

- Orientation: Vertical

- Measurement resolution: up to 3μm

- Measurement accuracy: up to ±3μm

| AVR200 | |

| X-Y-Z Travel (mm) | 200 x 100 x 200 |

| Z axis Measuring | Standard |

| X-Y Accuracy (µm) | E2 = 1.9µm +5L/1000 |

| Z Accuracy (µm) | E1 = 2.5µm +5L/1000 |

| Scale Resolution | 0.1µm |

| Zoom Optics | 6.5:1 |

- Dedicated 6.5:1 (2 LED) or 12:1 (3 LED) CNC zoom optics

- Quick-change bayonet or fixed lens mount for telecentric optics

- Interchangeable bayonet mount lenses - 0.3x, 0.5x, 0.8x, 1.0x, 2.0x, 4.0x telecentric optics and 6.5-1 manual zoom lens

- Auxilliary lenses for zoom optics: 0.5x , 1.5x and 2.0x

- Renishaw touch probe kit with 2 or 4 bay probe rack

- Programmable darkfield quadrant LED surface illumination for zoom optics

- DXF/FOV option for automatic comparison to CAD files

- Modular system work station

- Part fixtures and work holding devices

- Thread measurement software module

- CNC rotary axis fixture

For further information, please view the brochure or feel free to contact us. We are always happy to help.

Case Study

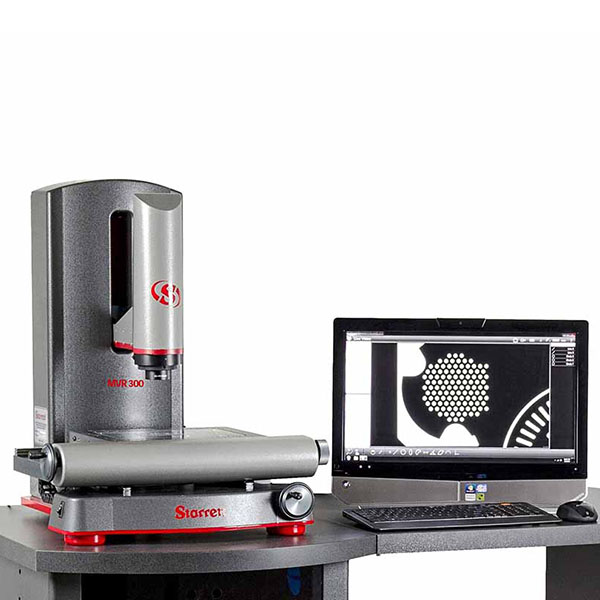

“The AVR300 is transformative – optimising processes and cutting down inspection cycle-times. The AVR300 is everything we needed in one machine. It’s invaluable for ensuring part conformance to meet sector requirements.” – Quality Manager, Jonathan Fraser