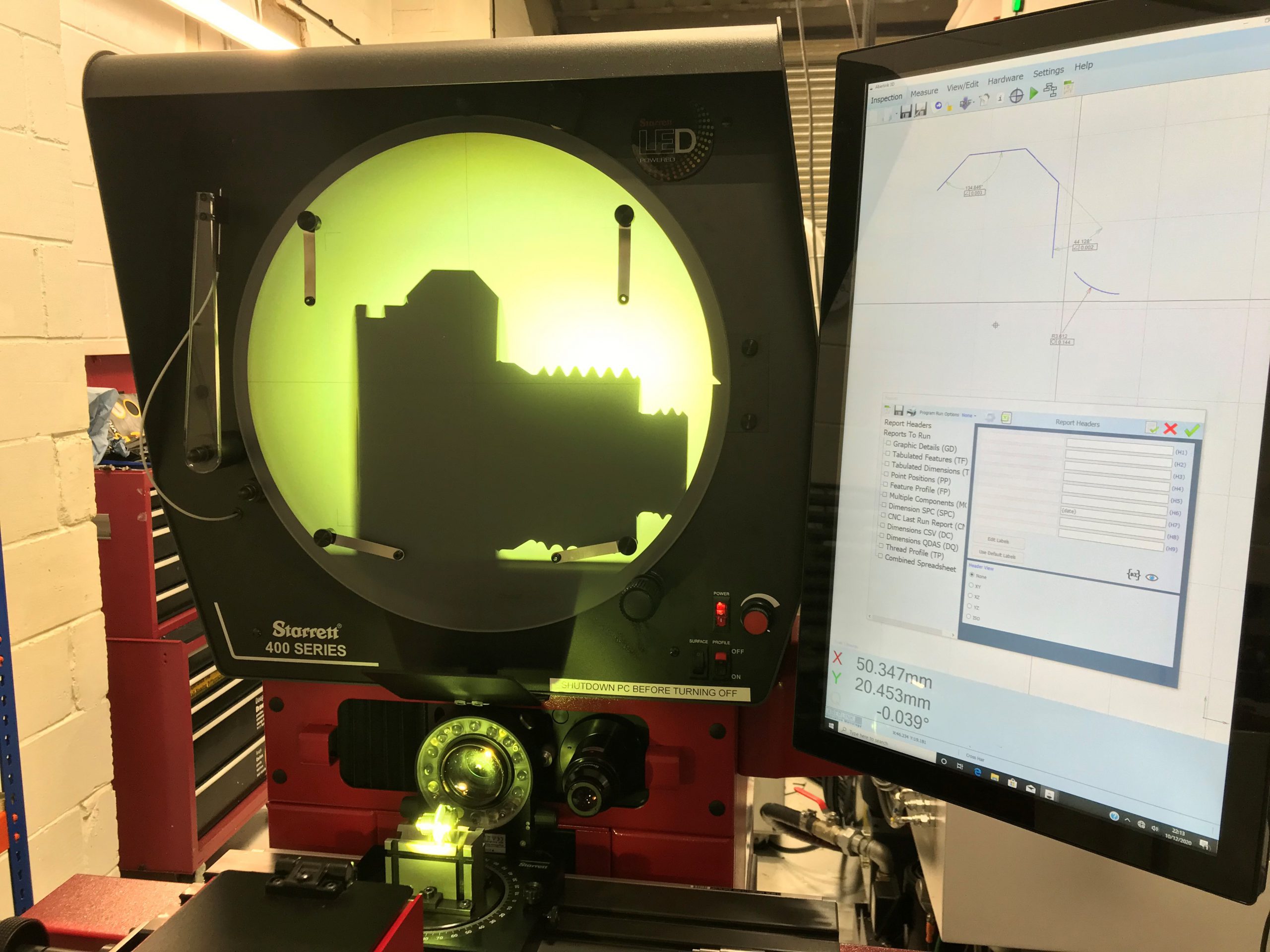

We speak to Howard, Managing Director of Sheldon Precision to discuss the impact of their newly purchased HD400 profile projector with advanced Optivu Synergy software.

Could you briefly summarise what Sheldon Precision does and the key industries you supply to?

We sub-contract CNC turning of precision components for a wide range of industries, such as Highways, Automotive, Aerospace, Fasteners and Hydraulics.

What motivated your purchase of the HD400 Profile Projector?

Its wide range of features and capabilities compared to our existing projector.

What applications are you using this product for? Who primarily operates it?

My shop floor staff use the machine daily for first article inspection and in-process inspection. The most common applications are linear and angular feature measurement.

How did the Optivu synergy software meet your requirement?

It enables us to confidently measure geometric features that we could not previously measure on the analogue projector.

How has this profile projector and software impacted your production and quality control processes?

The larger working envelope of the projector has made it easier to position larger parts for measurement, and there is a significant increase in confidence in the readings we are getting from the software.

What features make the profile projector and Optivu Synergy Software particularly well suited to solve your problem?

We machine a wide variety of size components and the dual-lens makes it very easy to switch between magnifications. Also the surface illumination ring light is very good and has meant I don’t need a vertical inspection machine. As mentioned, the software has helped with geometric tolerances and is easy to use.

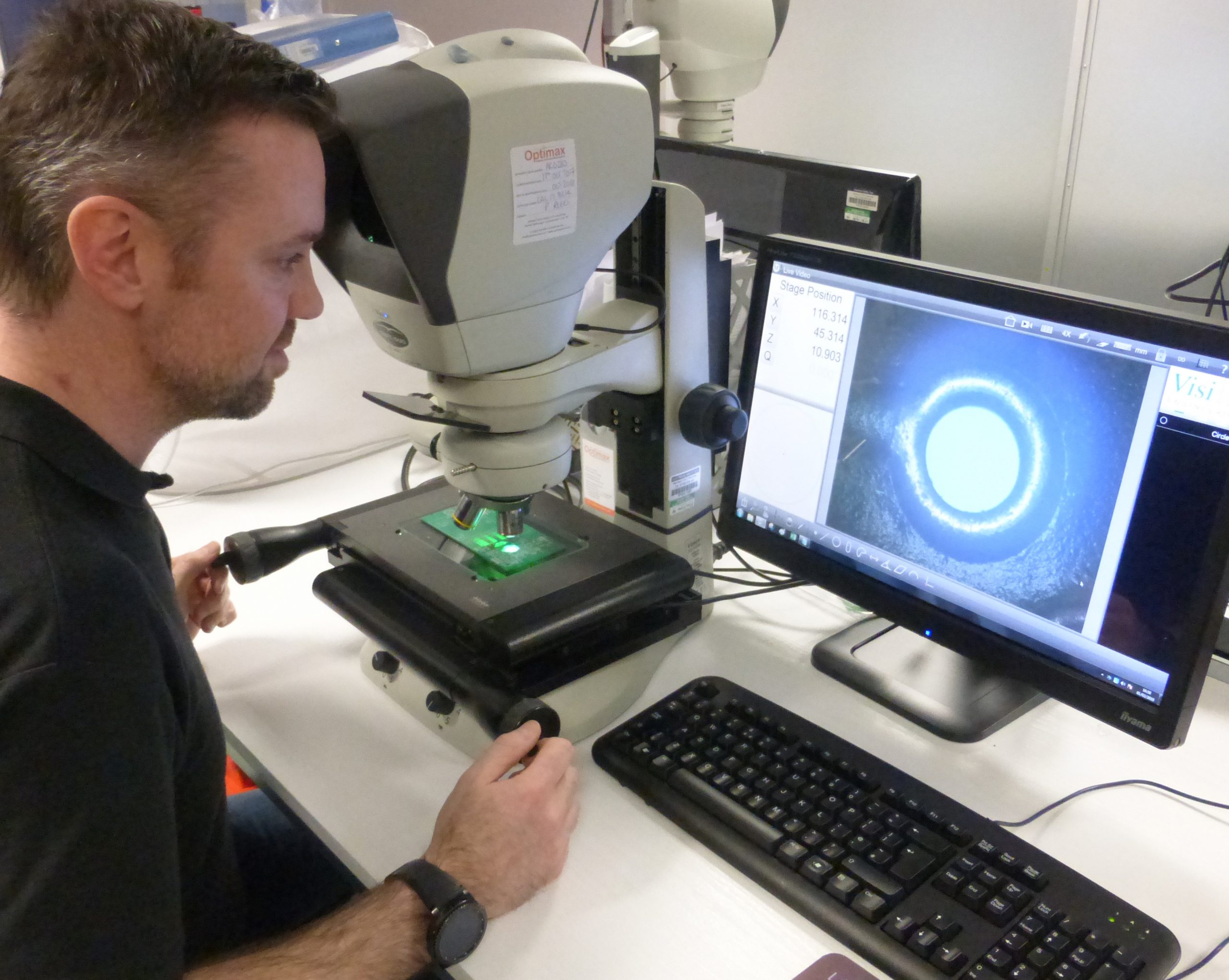

Why did you choose to buy from Optimax?

They had, in my opinion, the most advanced profile projector on the market.

Find out more about Sheldon Precision – https://www.sheldonprecision.co.uk/