Why push-out force is a critical factor of the press fit assembly process

In demanding applications such as electric vehicles (EVs), aerospace and industrial machinery, the reliability of electrical contacts in PCBs is critical. These applications expose components to vibration, thermal cycling, and mechanical shock that can cause traditional connections to weaken or fail, leading to intermittent signals, increased electrical resistance, or complete circuit failure. PCB verification is required during manufacture to ensure it meets the high standards required by these complex industries.

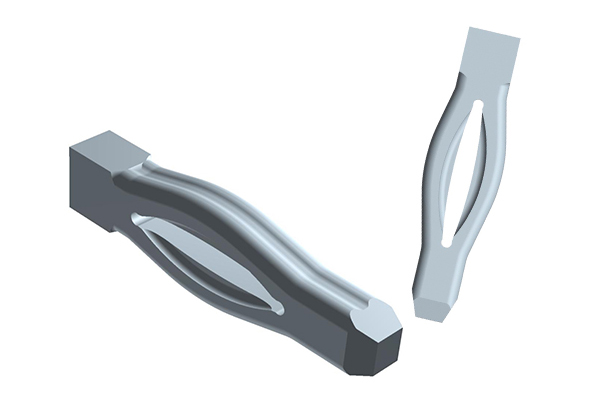

The EloPin’s high push-out force is important because it ensures a gas-tight and mechanically robust connection. The “cold weld” created during the press-fit process effectively deforms the pin and the PCB’s plated through-hole, this forms a connection that resists loosening. A high push-out force is a measure of the connection’s strength and ability to maintain integrity under extreme forces, preventing failures.

Measuring pull-out force as part of a press fit inspection regime

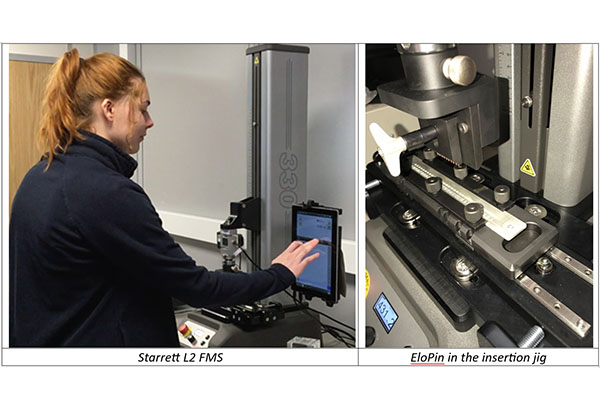

To ensure the press fit pin’s performance, manufacturers perform rigorous quality control tests, the pull-out (or extraction) force is a key metric. A PCB manufacturer is using a Starrett L2 force testing machine, supplied by Optimax, for this test. An EloPin is mounted in a PCB and held in a fixture, a precision grip pulls the press-fit pin out of the hole at a controlled speed. The Starrett L2 machine records the force required to extract the pin, that is compared against strict industry standards.

This press-fit inspection process ensures that every batch of pins have the mechanical strength to perform reliably. If the pull-out force falls below the specified threshold, it shows a weakness in the press-fit connection, which could lead to failure in the field. This systematic testing is vital to ensure the safety and longevity of the final product, especially in safety-critical applications where a single failure can have severe consequences.

L2 Systems

We recommend the L2 Systems, which feature a small footprint making them ideal for lean manufacturing environments and as a bonus, no programming experience is required. This is supplied with a purpose designed jig to hold a PCB sample and measure the force needed to insert then extract the pins. For this client, Optimax also provided training and support for the operators, wrote the test parameters (which include terminating the test if the insertion force exceeds limits), as this might indicate that the test pins are bent or misaligned. Being automated, the test can be carried out by shopfloor staff not trained in inspection.