Helping Honda meet customer expectations for a quiet ride

In the contemporary automotive landscape, marked by the increasing prevalence of electric vehicles and the pursuit of quieter rides, interior cabin noise management has emerged as a critical factor influencing product quality. Specifically, within the realm of NVH (noise, vibration, and harshness), an integrated approach is essential to meet evolving consumer expectations for a refined driving experience.

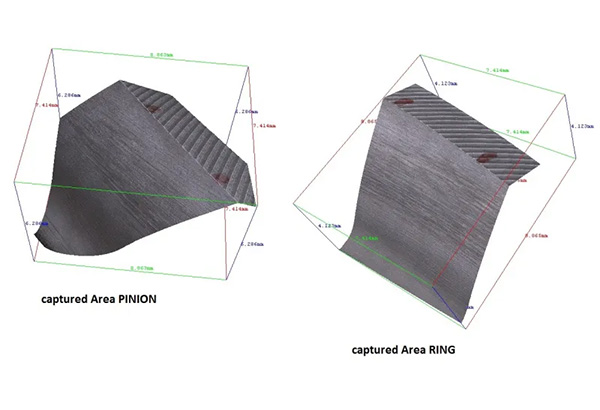

The gear system within a vehicle’s drive chain is a prominent contributor to undesired cabin noise. The intricacies of gear mechanisms, particularly the waviness on tooth flanks, have been identified as potential sources of disruptive sounds within a motor vehicle’s interior. Extensive research indicates that controlling and optimizing these waviness parameters can play a pivotal role in significantly reducing or eliminating these unpleasant noises.

Honda faced this problem, and it was recognised that one of the biggest challenges in measuring waviness on gear flanks is filtering the waviness and roughness of the surface. For Honda, conventional 2D imaging techniques did not provide the required results. The waviness is often superimposed by tool marks caused by the machining process, which makes it difficult to isolate them completely from the roughness. 2D surface profiling methods or tactile measuring systems, which only capture single profile lines, are only partly suitable for this purpose.

Our advanced laser micromachining techniques offered a new route

By implementing advanced laser micromachining techniques, manufacturers can precisely manipulate the surface characteristics of gear teeth, mitigating irregularities and enhancing the drive chain’s overall acoustic performance. This meticulous control over gear components exemplifies the role of innovative technologies in addressing the nuanced challenges posed by NVH in the automotive industry, thereby elevating the standards of comfort and quality for modern vehicles.

It became clear that Ra values are insufficient to verify the real surface state of flanks, as they only capture single profile lines. With area-based Sa-values, we can map surface features over the entire surface and then completely isolate them from the waviness using various filtering methods. The results of this analysis have enabled Honda to adapt the manufacturing process of hypoid gears and, consequently, to help prevent noise in the production of hypoid gears. Using high-resolution and area-based measurement technology, Honda has successfully isolated and quantified the waviness from the roughness on a gear flank. This was achieved using Optical 3D metrology, which enables the surfaces to be accurately measured, provides surface characterisation parameters, and allows manufacturers to alter their production to suit the new requirements.

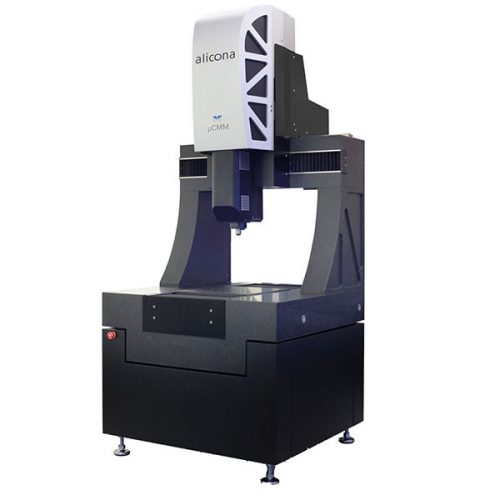

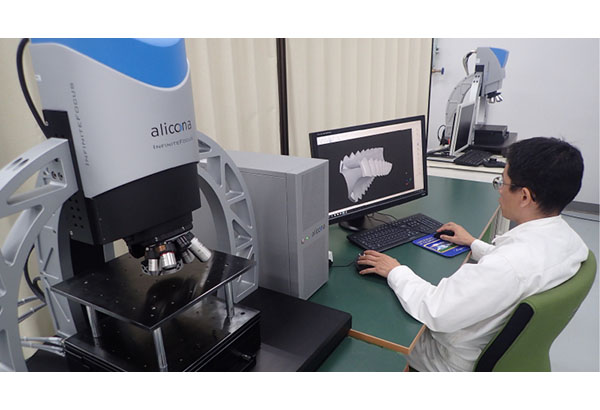

InfiniteFocus G6

InfiniteFocus G6 is an accurate, fast, and universal optical 3D measuring instrument designed for measuring optical surface roughness and shape, particularly for smooth and highly polished surfaces. Operating within the µm and sub-µm range, this device provides precise results regardless of component size, material, geometry, weight, or surface finish, all accomplished with only one optical sensor.

This innovative measuring device combines the functionalities of a roughness measuring system (Ra, Rq, Rz/Sa, Sq, Sz) with the characteristics of a coordinate measuring machine. Its robust Focus-Variation technology and vibration-insensitive design ensure high-resolution and repeatable results, even when directly next to the machine tool.

In addition to its exceptional performance in manufacturing settings, the InfiniteFocus G6 offers seamless integration with CAD systems for offline measurement planning. Furthermore, the device has an automation interface enabling fully automated measurements, making it an excellent choice for production environments. The Alicona Infinite Focus G6 is particularly suited to this application due to its ability to measure steep flanks, its 250mm x 250mm measuring area and of course the Advanced real3D rotation unit. The Measuresuite software makes visualising the data straightforward , and the instrument is suited to both repetitive measurements in a production environment and research and development work.