Time consuming measurement is a huge issue

It is well known that human inspection is not 100% effective. Fatigue, distractions, and boredom conspire to prevent defects from being spotted, particularly if those defects are not obvious. Detailed examination, potentially using templates, images, or measurements, is a time-consuming process, and manual inspection is not suitable for use in a production line with large numbers of components.

With AI, there’s a speedier solution

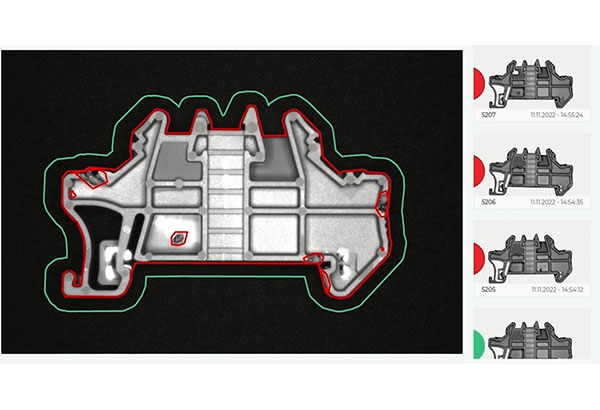

The Inspekto autonomous machine vision system uses a camera and a powerful AI (Artificial Intelligence) image processing system to spot defects whilst minimising false positives. The system is trained using good components and can be configured to ignore product parts that differ by design (such as serial number labels). It tolerates orientation and positioning and can scan components placed in the camera’s field of view and on a conveyor belt at rates exceeding 40ppm. These defects are identified in red on the displayed or recorded image to facilitate rework.

The S70

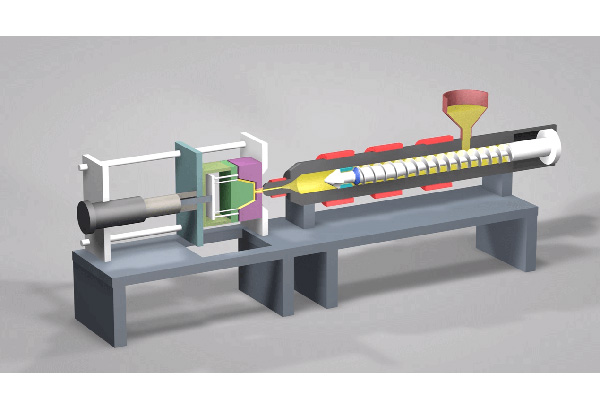

The S70 can be used on many materials/components, including Electrical Components, Metal, PCBs, plastic, and rubber. This capability makes it an ideal solution for products such as injection moulded components where it can identify sink marks, pores, dents and flashing, electrical connectors-presence/missing/position, soldering on PCB’s, integrity & milling swarf in metal components, position and presence of labels, verification of coatings and O ring placement.