Aircraft engine inspection methods have moved on considerably

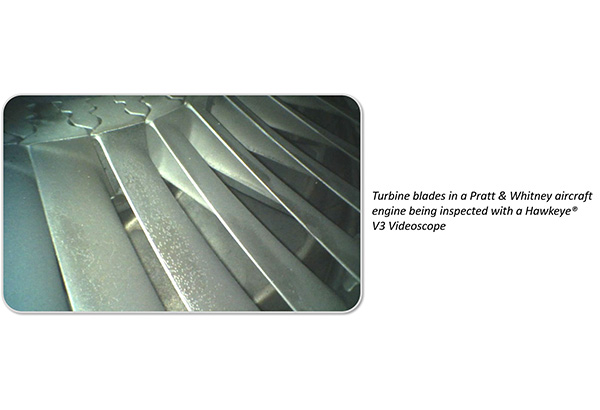

The benefits of borescope or endoscope inspection of hard-to-reach parts of airframes and aircraft engines are well known, and there cannot be many repair shops which do not have these available. But the technology has advanced significantly, in regards to both resolution and clarity of the image. Not only that, but the ease of use and new features has advanced. One particular change has been the ability to share images in real time and record still images and video, ready for discussion with second- or third-line repair or reporting back to a client.

Meet the new generation of borescopes

The new generation of borescopes offer a wide range of features. Take the Hawkeye V3 HD, which has an HD daylight readable colour touchscreen display, Wi-Fi connection and data storage. The quality of the images, ease of use and ability to share for a second opinion enables rapid identification of defects or elimination of suspected causes makes this just one example of the changing spec of modern borescopes.

The Hawkeye V3 HD by Gradient Lens

The Hawkeye V3 HD by Gradient Lens is just one example of the new generation of borescopes. Featuring a new micro-HD camera with integrated adjustable LED illumination and 4-way articulation, it is available in a range of lengths and diameters. The V3 Deluxe Kit also includes the 90-degree tip, Close Focus Tip, Neck Strap, Tripod, and extra battery.