Speedy inspections for packaging experts Rosinksi

Packaging manufacturers Rosinski are pivotal in providing packaging solutions primarily using polypropylene and polyethene for various products, including household chemicals, parapharmaceutical items, and cosmetics. Yet the perpetual need to adapt their product portfolio to align with evolving technological advancements, shifting customer preferences, and emerging industry standards meant a constant evolution in manufacturing processes.

With new designs, Rosinksi needed to meet the industry’s stringent quality standards. This required allowing for quick adjustments and implementing reverse engineering techniques.

3D scanning offers a reliable solution

3D Scanning using structured light provides a solution, and a tool such as the eviXscan 3D Pro+ scanner provides the ideal solution for the client. With the implementation of an eviXscan 3D solution, they can support orders they previously could not accept due to a lack of technical documentation from the customer. The customer provides a reference product, scans it, and makes a CAD model from the scans. Finally, a production mould is prepared. 3D scanning technology significantly reduced the preparation time of molds and tools necessary for production.

The use of eviXscan 3D Pro+ scanner in the quality control department allows for precise control of the quality of finished products by comparing them to original CAD models supplied by customers. This allows the company to be confident that products meet the expectations of the contracting customers. The implementation of eviXscan 3D solutions enabled precise quality control of finished products and shortened production times.

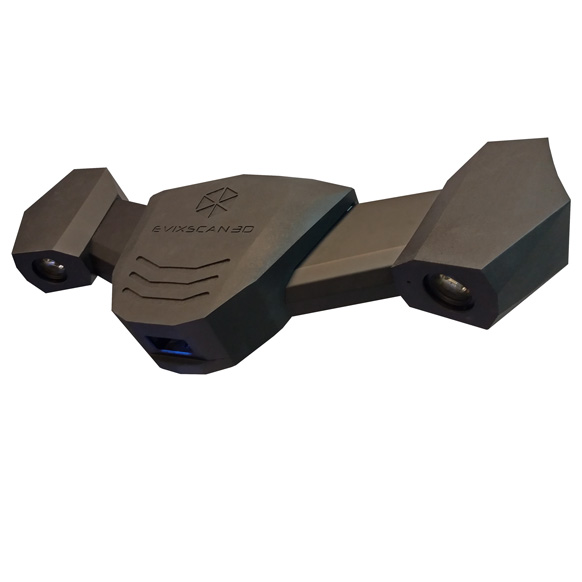

3D Optima+ scanner

The product we recommend is the 3D Optima+ scanner. Optima+ M provides a high density of scanning points (117 pts/mm2) and high accuracy (declared accuracy up to 0.009 mm according to VDI/VDE p2 Ps). In addition, Optima+ M has a reduced distance between the scanner and the object by 230 mm, which facilitates the operation of the measuring device during scanning.

Robotized systems are another area where the new Optima+ M scanner can be used. Its lightweight, compact design makes it easy to integrate with a robot. The scanner also has dedicated software for Universal Robots, which guarantees smooth system implementation and straightforward operation. An additional advantage of Optima+ M is the possibility of cooperation with the entire portfolio of accessories.