Quality assuring camshafts to exacting standards

The role of production metrology is expanding in conjunction with improvements in manufacturing processes. Given the ever more stringent accuracy requirements and falling cycle times in production (turning, milling, grinding, etc.), rapid measurement directly at the point of origin of the product, with rapid feedback to the manufacturing process to avoid waste, is important. Quality assuring camshafts and small rotationally symmetrical workpieces can be time-consuming due to the number of measurable points and parameters. Techniques using micrometres or profile projectors will give a partial dataset but are limited by the camshaft’s complex geometry and 3D form.

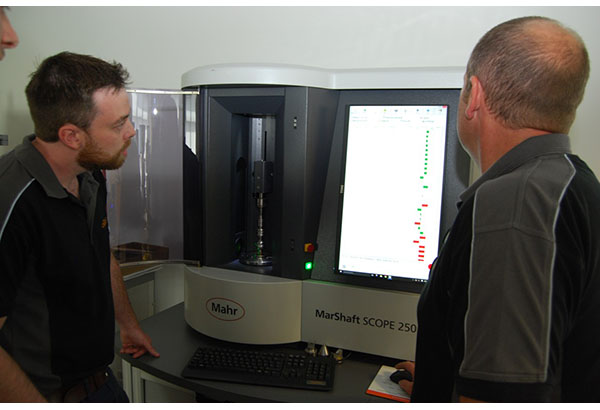

Automated shaft measuring improves processes

The future lies in automated shaft measuring machines that can deliver fast measurements with precision. Tools such as the MarShaft 250 have a wide range of features, such as a high-resolution CMOS camera matrix camera. Zoom functions and measurements are fully automated.

The main dimensionally critical features are defined as Length, Diameter, Form and position tolerances, Offsets, Recess width, Bevel width, Intersection points, Angles of rotation, Radii, Position of radii, Taper length, Hole contours, Angles, Pitches, Widths across flats and Outer threads. All parameters can be automatically obtained and presented in a report form.

The Marshaft 250

The MarShaft 250 plus is an automated shaft-measuring machine that delivers a fast and precise measurement of rotationally symmetrical components of up to 250mm in length. The high-resolution CMOS camera acquires 120 images per second (live image) with an image field of 1088 x 2048mm, keeping measuring time to a minimum. Users benefit from the high measuring accuracy of the matrix camera. Zoom functions allow the smallest details to be measured, which with conventional measuring methods are difficult, if not impossible, to test. The measuring station is designed for the smart factory of Industry 4.0: Measurements are fully automated, and workpieces can optionally be recognized via the barcode reader. MarWin Easyshaft software is the measuring, control, and valuation program for the Scope Plus series. The familiar Windows user interface and touchscreen make it intuitive to develop time-optimised measuring programs, and parameters and tolerances can be set to automate the pass/fail decision. Reporting is available directly to a printer or stored against the component identifier.