High volume inspection can be a challenge

In busy avionics manufacturing and repair shops, our eyepieceless ergonomic microscopes are ideal for high volume inspection whilst the greater stand-off distances facilitate rework. UV lighting is available for crack detection and inspection conformal coatings, and image capture enables a permanent record to be kept.

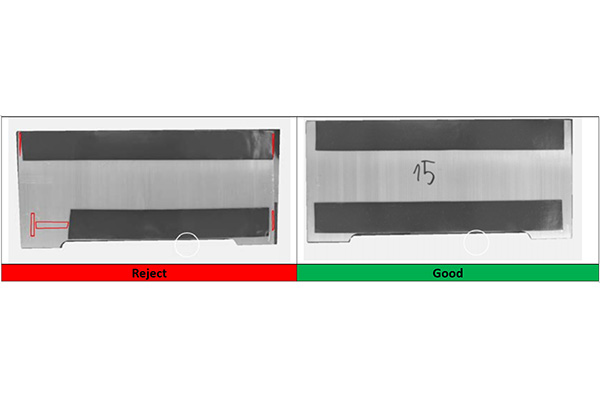

Advanced AI is trained to detect defects

Connectors and wiring harnesses are critical to the reliability of the avionics and so of the aircraft; our Inspekto visual inspection systems use AI to reject non-conforming products whilst endoscopes can be used to find wiring loom damage in situ. For even more detailed measurement of connector pin damage and wear, our Alicona surface profiling instruments are ideal.

Inspekto S70

The S70 can be used on many materials/components, including Electrical Components, Metal, PCBs, plastic, and rubber. This capability makes it an ideal solution for products such as injection moulded components where it can identify sink marks, pores, dents and flashing, electrical connectors-presence/missing/position, soldering on PCB’s, integrity & milling swarf in metal components, position and presence of labels, verification of coatings and O ring placement