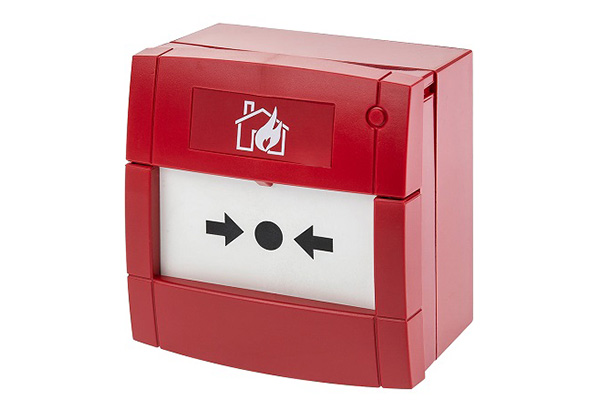

Helping fire safety manufacturer KAC Alarm Co save time with in-house testing

Manufacturer of fire safety products The KAC Alarm Company creates over 1.5 million manual call points a year, as well as evacuation devices used in commercial fire and security systems. While PCBs and some components for assembly were purchased outside the company, KAC had its own moulding shop operating around the clock supplying 90% of the plastic components required. KAC had outsourced measurement, inspection and environmental testing of finished products but this was impacting speed, with parts delivery and testing leading to significant delays.

A multiple contact solution customised for long-term gains

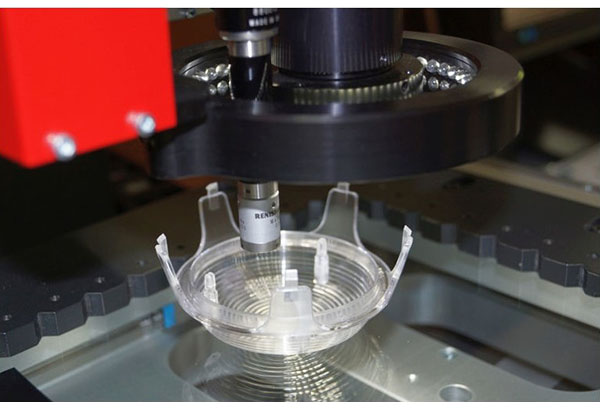

The customer were aware of the many options available but wanted to focus on longevity and quality. We recommended the Starrett AV300 which would allow both an optical and a cintact probe with a 300mm measuring range in the X-axis, along with the ability to accommodate both mould tool inserts and components up to 18kg.

As they told us: “It was not just about the functionality and capability of the equipment – we particularly liked the service offered by Optimax. The support and post-sales care, as well as the training, was one of the key factors. There was a willingness to manipulate the system software in a way that suited us, with additional modules that Optimax coded and added on to the base software. We knew a vision only system would not cover everything we do. The Starrett AV300 covers 99% of what we have to measure, which is why we wanted the combination of both contact and non-contact sensors. The time savings for the checking and validation of established and new components has been significant, and, working with Optimax has provided us with a feeling of security. We know we will not be left struggling to find answers to any measurement issues.”

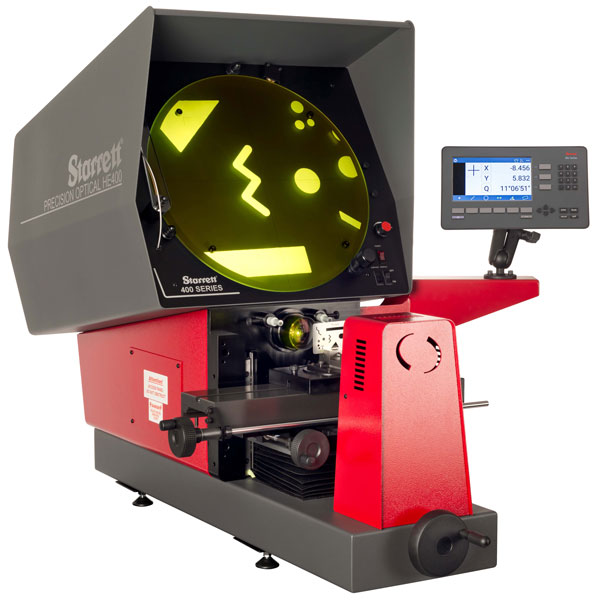

Starrett AVR300 CNC video measuring system

Upgrade to the AVR300, a CNC vision system fitted with an optional touch probe sensor and probe rack. The machine’s huge magnification range with 12:1 zoom optics and its segmented, height-adjustable LED ring light deliver optical measurement capability, while the touch probe enables accurate measurement of 3D features such as cylinders and cones that are out of the sensor’s line of sight.