The Cheaney Shoe brand represents the finest British craftsmanship, producing premium footwear handcrafted from start to finish in their original 1886 Northampton factory.

From cutting the leather to stitching and final polishing, the entire process is conducted using the same methods developed by Cheaney from the very beginning. Cheaney has a highly skilled and experienced workforce and retains a strong reputation as one of the top English shoemakers chosen by discerning buyers across the world.

The first stage of the manufacturing process of the shoes is the cutting out (‘clicking’) of the quality leather. Cheaney work with the best tanneries in Europe to secure the finest leather for their shoes, but as a natural material even the finest leather can have wire and vein marks that need to be picked up early in the manufacturing process to avoid having rejects later in the process.

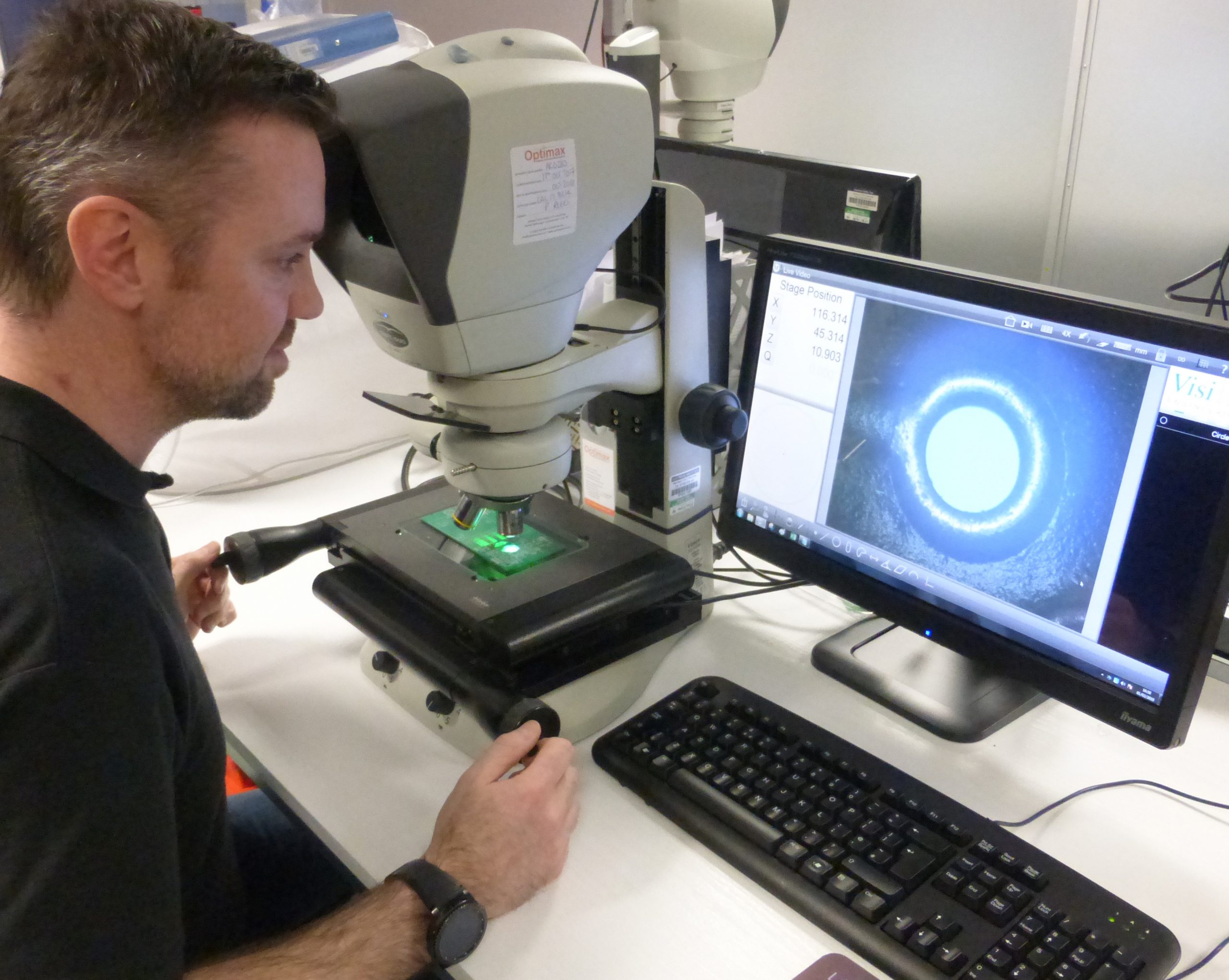

In the past this was performed with the human eye, but they have now invested in equipment to enhance the human eye inspection with a Mantis Compact microscope to ensure that they can pick up these faults as soon as the leather has been cut out. Lesley Tartaglia, Clicking Room Examiner, inspects thousands of sections per week to ensure that they are of the highest quality as they continue the 8 week process and 200 hand or hand tooled operations involved in making a pair of Cheaney shoes.

The Mantis Compact is bench mounted and allows Lesley to inspect the individual pieces of leather with a comfortable viewing position. The ergonomic design allows the user to wear glasses and have freedom of head movement, reduced eye fatigue, a long working distance and most importantly allows better hand to eye coordination which is crucial when inspecting large volumes of sections each week.

Cheaney Shoes purchased the Mantis Compact from Optimax Imaging Inspection and Measurement and found it invaluable to be able to bring samples of the leather to their showroom in the Midlands. This allowed them to try a number of different solutions to see which would work best for their application. Optimax always take the time to understand each customers application so they can offer the best solution available to them and UKAS accreditation ensures the highest possible quality and accuracy.

Alex Bateman, Factory Manager at Cheaney Shoes commented ‘We have already seen a return on our investment. We were hoping that the Mantis Compact would pay for itself by reducing the number of rejects within a year when we first purchased the equipment, but we are currently seeing a vast improvement of 25% of rejects that are now being picked up at this crucial first stage. It is now a key piece of kit in the clicking room to ensure that we continue to manufacture shoes to the highest quality standards that people expect when they purchase a Cheaney shoe’.

For more information on Cheaney Shoes visit www.cheaney.co.uk