Offering client support for measurement of precision plastic mouldings for insulation

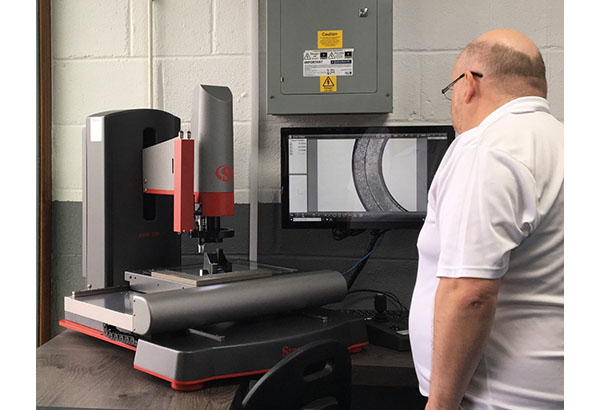

A customer whose product range includes coil bobbins and electrical insulation solutions recently approached us for a combined optical and tactile measurement solution to support their electrical and automotive products. They wanted a versatile solution that could be used particularly for automotive components, to generate the data behind the Initial Sample Inspector reports and the Production Part Approval process.

Our solution offers true versatility

The manufacture of precision plastic mouldings in a variety of engineering polymers requires accurate optical measurement, both to determine the capability of the moulding process and to quality-assure the parts produced. The use of black, white, or clear polymer makes optical measurement even more challenging, but tactile methods of measurement cannot be used because of potential damage.

Our client’s capability studies alone demand numerous precise measurements on more than 50 parts, so repeatability and speed were also requirements. We recommended the AVR300. One key benefit was that the client could have pre-programmed measurement routines for complex parts, so shop floor staff could carry out the measurements with minimal training.

In their own words? “The AVR300 is everything we needed in one machine. It’s invaluable for ensuring part conformance to meet sector requirements.”

AVR300

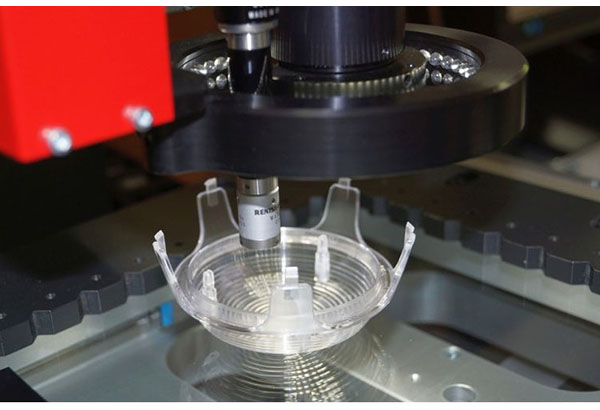

Optimax specified the AVR300, a CNC vision system fitted with an optional touch probe sensor and probe rack. The machine’s huge magnification range with 12:1 zoom optics and its segmented, height-adjustable LED ring light deliver optical measurement capability, while the touch probe enables accurate measurement of 3D features such as cylinders and cones that are out of the sensor’s line of sight.