We are optical calibration experts

UKAS accredited since 2015, our lab is assessed to ISO17025 and we are pioneering in our approach. The first lab in Europe to win approval for calibrating both CNC vision systems to ISO10360-7 and Optical shaft instruments.

Our engineers don’t just calibrate, they clean, adjust and make minor repairs as standard, ensuring they continue to work at their best. If more extensive repairs are required, we will quote before doing anything further.

Our customer care team track your assets, sending timely reminders, set at an interval to suit your environment. Pricing can be locked in for extra piece of mind, guaranteeing the price you pay over a three year contract.

Our UKAS schedule covers:

- Height gauges – simple & complex

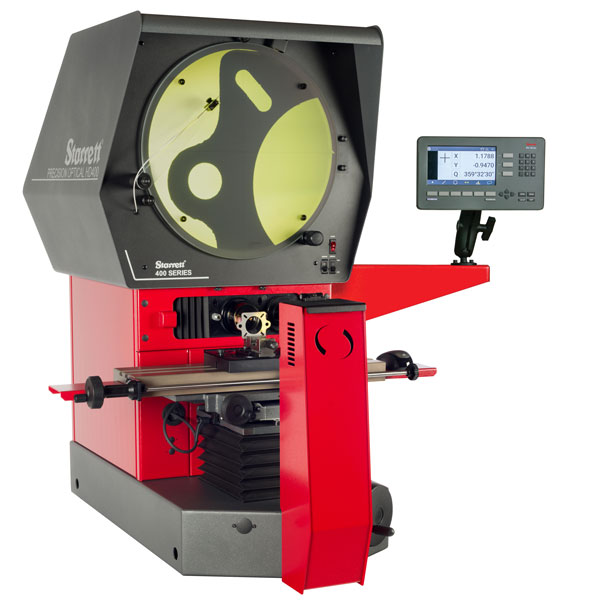

- Shadowgraph – with DRO or PC Software

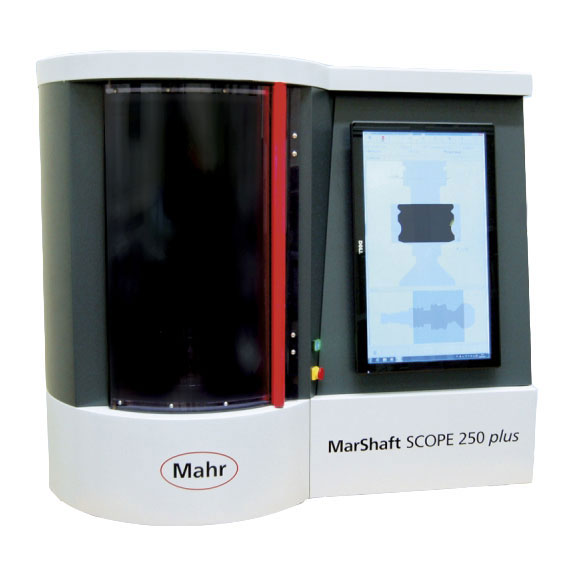

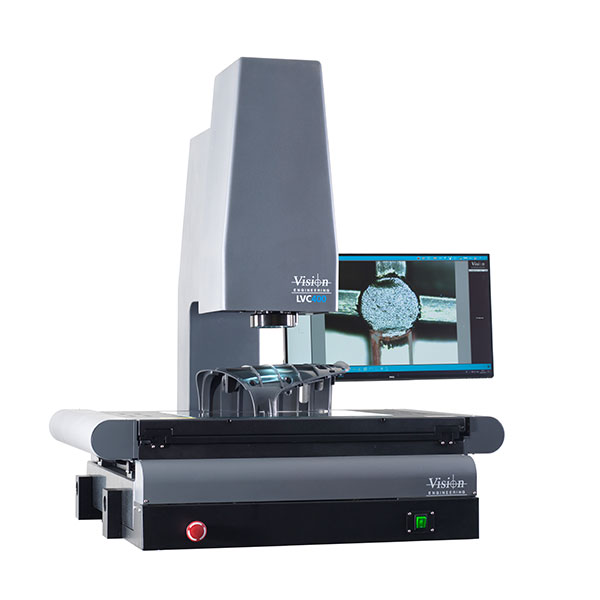

- Vision CNC systems – either inhouse or to ISO10360-7, with Probes, laser and Q axis

- Manual Vision systems – 2&3 Axis

- Digital Microscopes

- Optical Microscopes

- Field of view Vision instruments

- Toolmakers microscopes – DRO or PC Software

Inhouse Schedule covers:

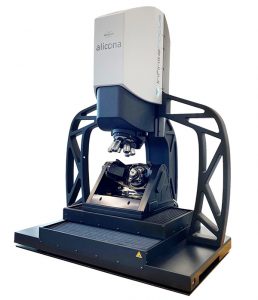

- Alicona – all variants – based around ISO10360-8

- 3D Scanning

- Service calibration and repair for

- Starrett

- Vision Engineering

- Alicona

- Hawkeye Gradient

- Mahr

We have a large inventory of new consumable spare parts and also probably, one of the largest stocks of components and spares for Non-Contact Measuring instruments no longer in use.